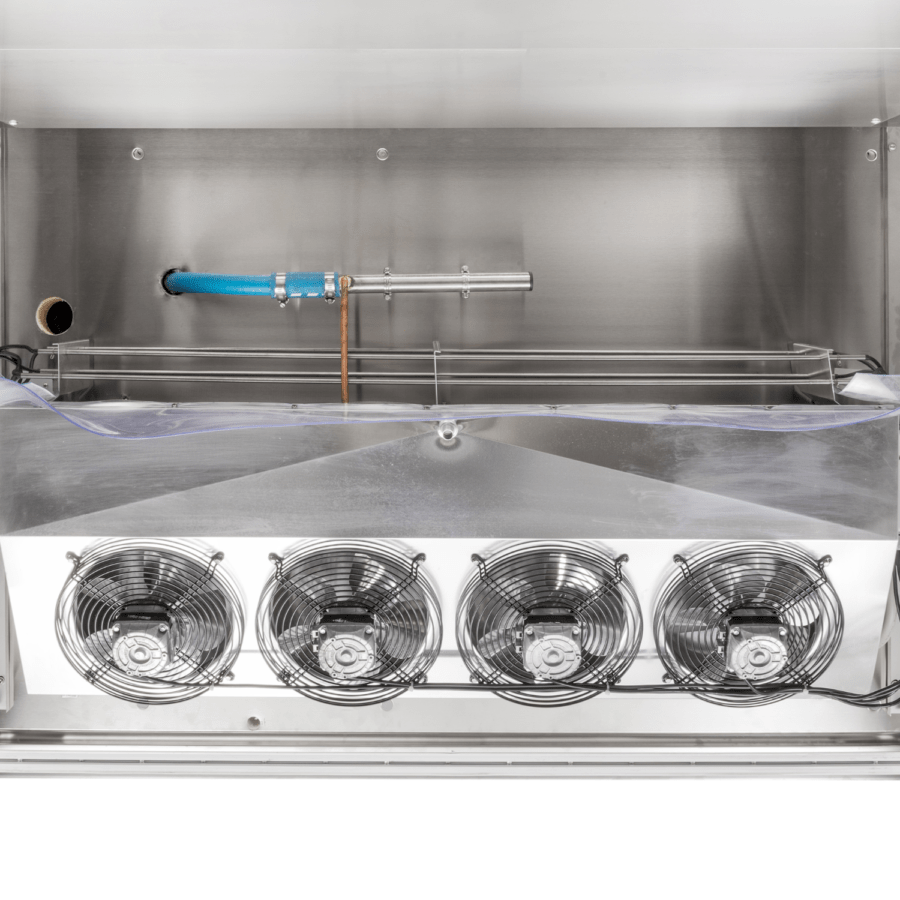

The “Retarder Proofer” proofing-cooling room, or in Hebrew Retarder Proper, is an advanced solution in the field of baking that allows for maximum control over temperature and relative humidity. In the last step of the operation cycle, the room changes from a cooling room that was used to store the products to a heated room that allows the bakery products to rise. In this way, baked goods can be stored in the refrigerator overnight or over the weekend, and at the given time programmed, the products will be ready for baking after rising.

The benefits of using Retarder Proofer

The proofing-cooling room maximizes the proofing process thanks to precision in the level of heat and humidity, which improves the flavors and allows for a very natural proofing process, this is a significant change in the way of thinking and working in everything related to proofing and baking.

A revolution in the baking process

Modern technology allows the Retarder Proofer to be an almost guaranteed system for the success of the baking process. This innovative device is among the most important inventions in the field of baking today.

How It Works ?

The baker can now plan the working day and plan the production in advance. The biggest savings in using chill-blowing is time. In the traditional process, production must be started early in the morning in order to:

- Knead the dough

- design and put in a mold

- Allow the product to rise

- Put it in the oven about two hours after starting work

Saving time and money

Using a swelling-cooling system in the bakery allows the work process to start in the morning (or at any time chosen), when the products have already risen and are ready for baking. In this way, about two hours of work are saved each day, which makes it possible to produce the products that will be baked the next day and put them in the Retarder Proofer. The baker can sleep two extra hours every day and still put the products in the oven at the same time since the rising process is done automatically in the system.

In addition, using the Retarder Proofer is a significant saving in personnel and wages. It allows the baker to prepare additional products while the existing products are already in the swelling process, thus saving on manpower returns the investment in a very short time.

Suitable for any factory

Retarder Proofer swelling-cooling systems exist in a variety of sizes and options, and the necessary system can be adapted for any purpose, even for small factories.

The Retarder Proofer system is definitely a revolution in professional baking, and those looking to improve the rising and cooling processes in their kitchen will find a perfect solution. Today, you can take your products to the next level and ensure maximum quality in every baking.