Description

A delayed proofing system is built as a cupboard with insulated shelves for baking molds or an insulated room that is a refrigerator or freezer, which when necessary performs in a controlled manner controlled by a computerized controller the defrosting, the preparation of the product for proofing and proofing.

The result is a quality bakery product that has been thawed and risen in the correct way and is ready to be baked at the time requested

The perfect result of proofing using the delayed proofing method is thanks to :

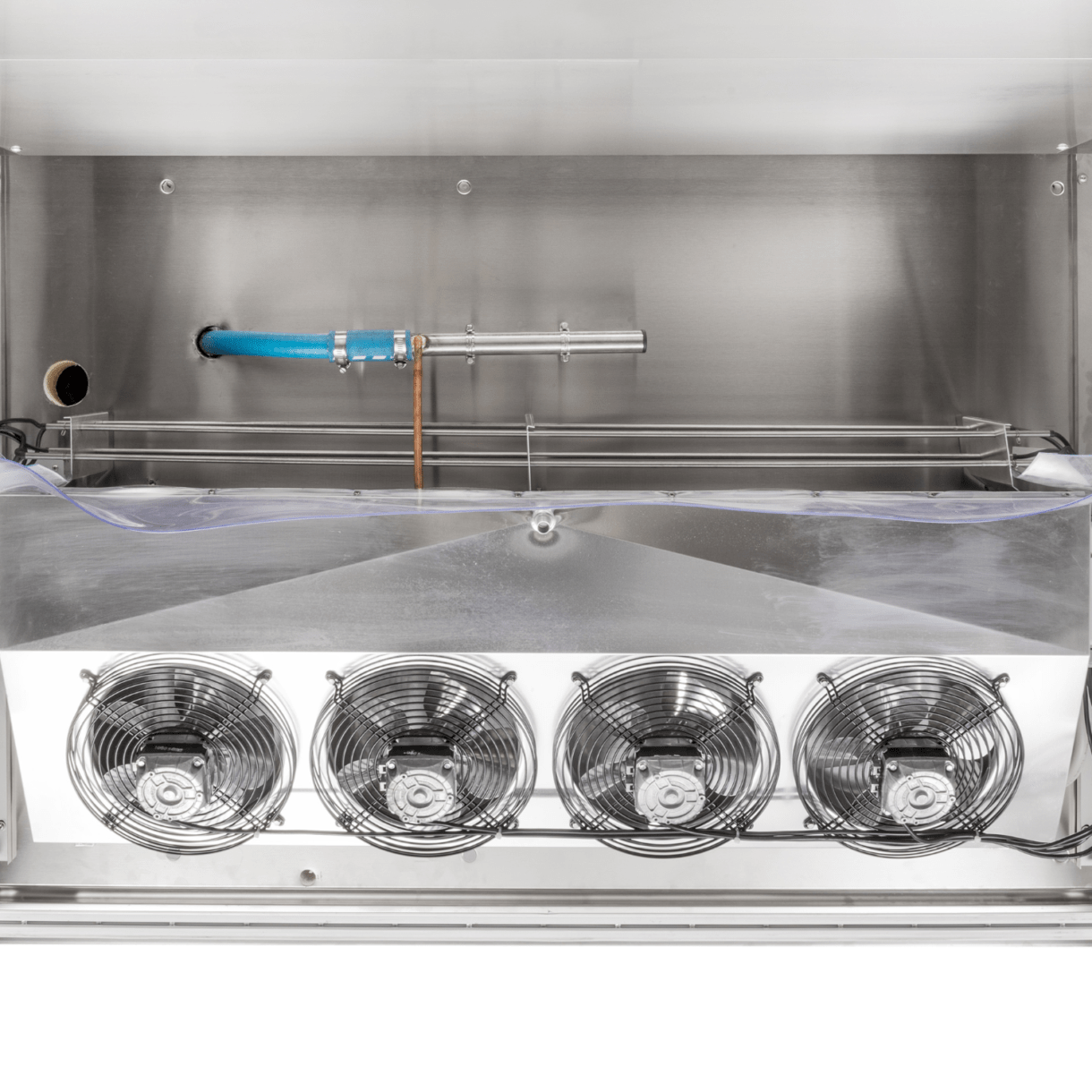

- Correct balancing of the cooling system

- Advanced heating and humidity system

- Uniform air control system in all compartments

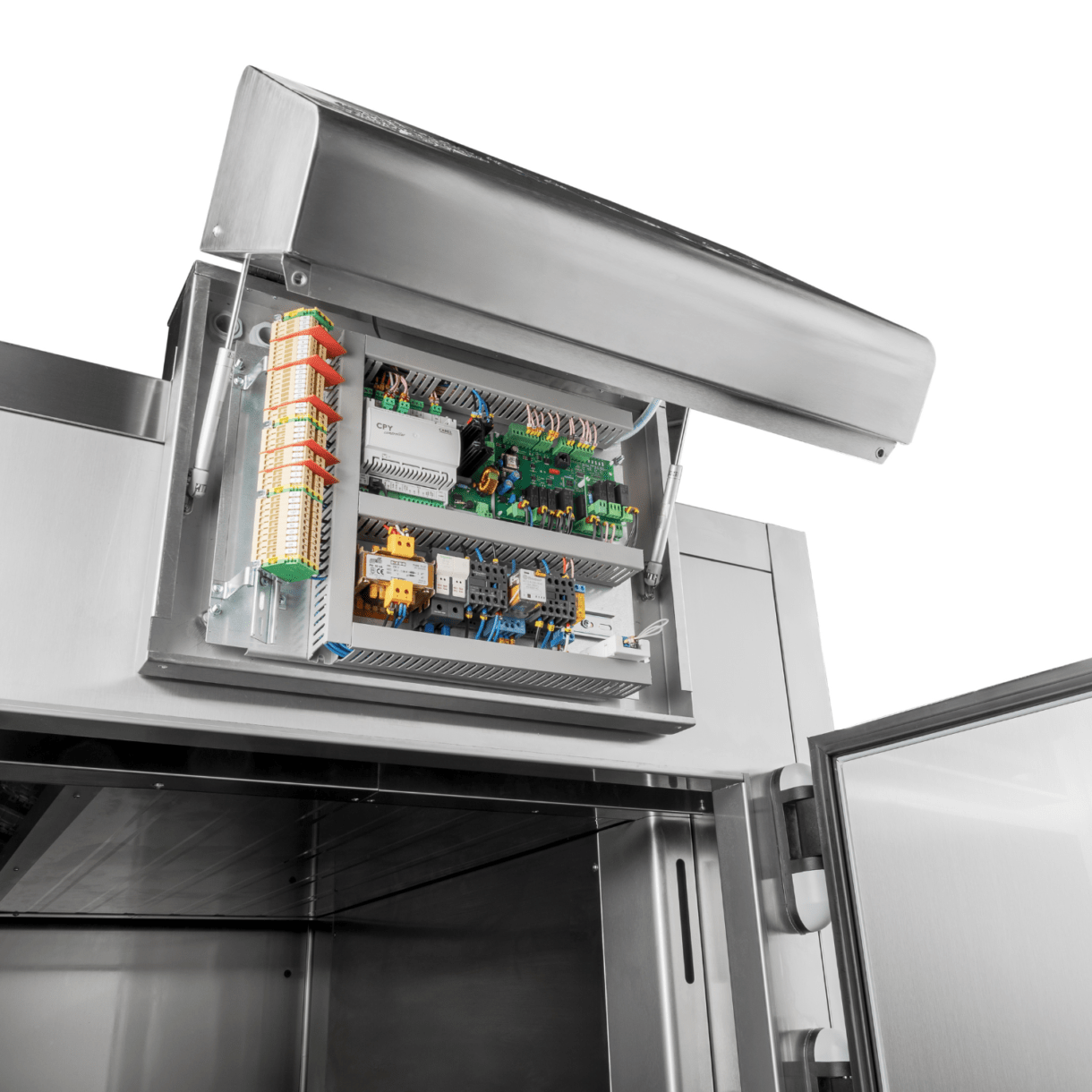

All cooling systems are adapted to tropical weather and are made of extremely durable materials, making them a perfect solution for bakery equipment , bakery refrigerators , and businesses that require controlled dough rising . The control system can be digital, LCD or PLC depending on the customer’s requirements and the type of activity in the bakery or confectionery. The systems manufactured by IRTEC can be ordered in different sizes and for controlled rising or storage of doughs with a capacity of one cart up to dozens of carts in one room, when they will all rise with the same uniformity.

The system is especially suitable for anyone looking for a professional delayed proofing system , advanced confectionery equipment , or smart storage and proofing solutions for baking businesses.