Description

The production of the conventional dough is done with a manual or computerized dough rolling machine.

Factories where the required dough yields range from hundreds of kilograms per hour to several tons per hour will be found at Y. Gottlieb is an ideal solution for any type of dough, production process, required production quantity and in the highest qualities.

Automatic production of dough in a precisely planned and adjusted production system improves the quality of the product, saves manpower and raw materials.

Rondo, which we represent in Israel, is the leading company in the world for the production of production systems for dough as a raw material and continuous rolling systems for feeding the production lines.

J. Gottlieb is credited with installing the most automatic dough production systems in Israel

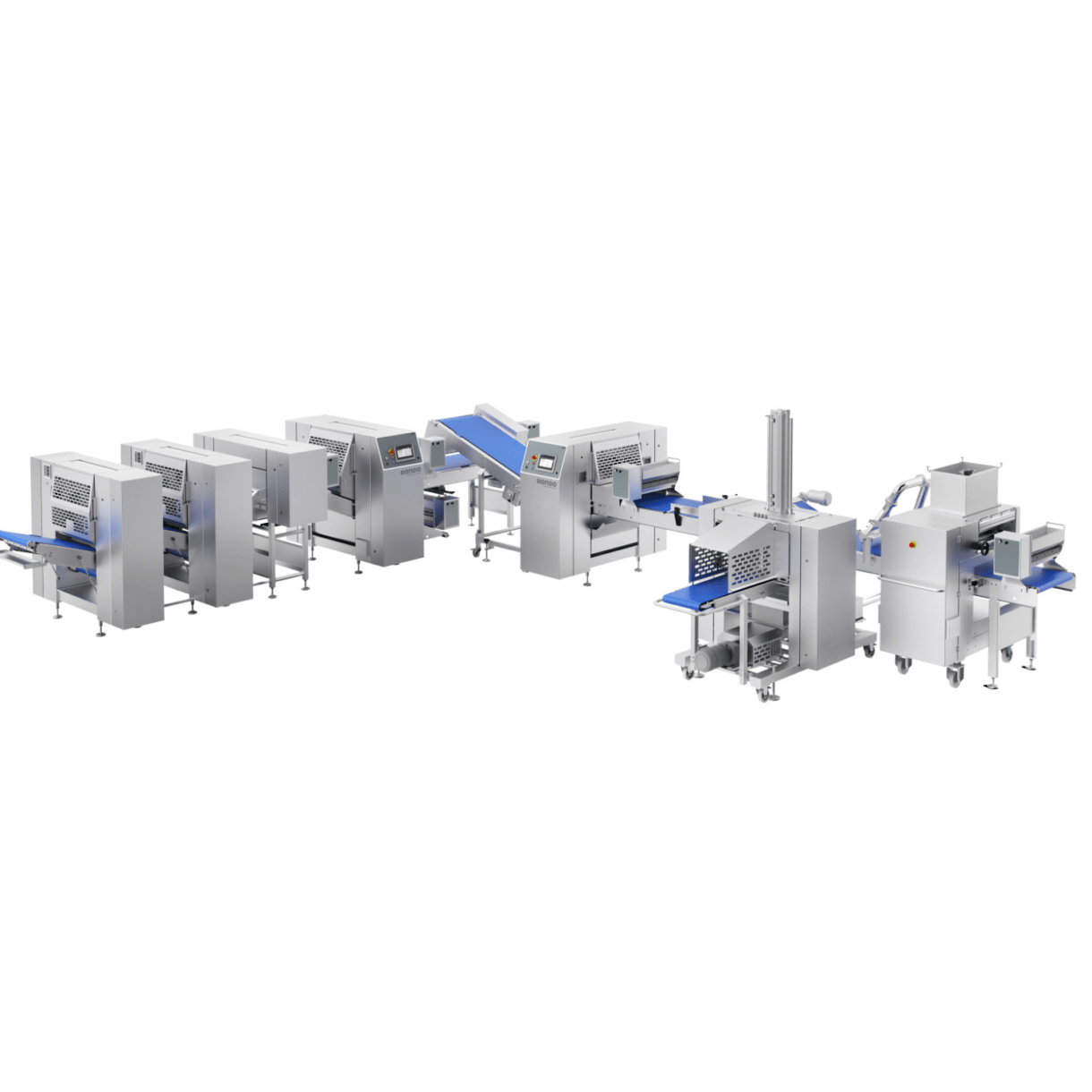

MLC stands for Modular Laminating Concept; “Modular flooring systems”.

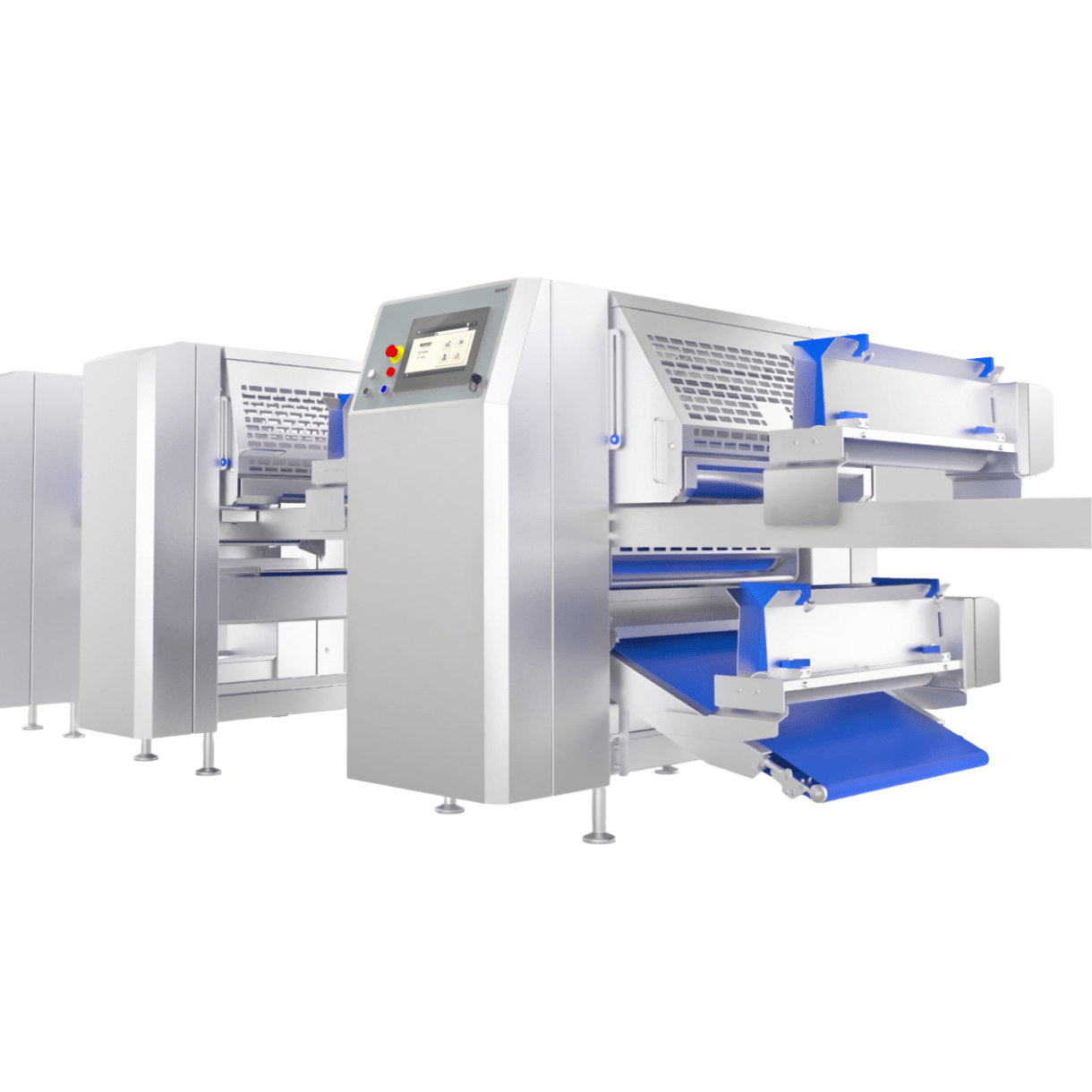

RONDO MLC is the innovative concept for automatic production systems for dough. Continuous, efficient and high-quality production of dough that is continuously produced and rolled out.

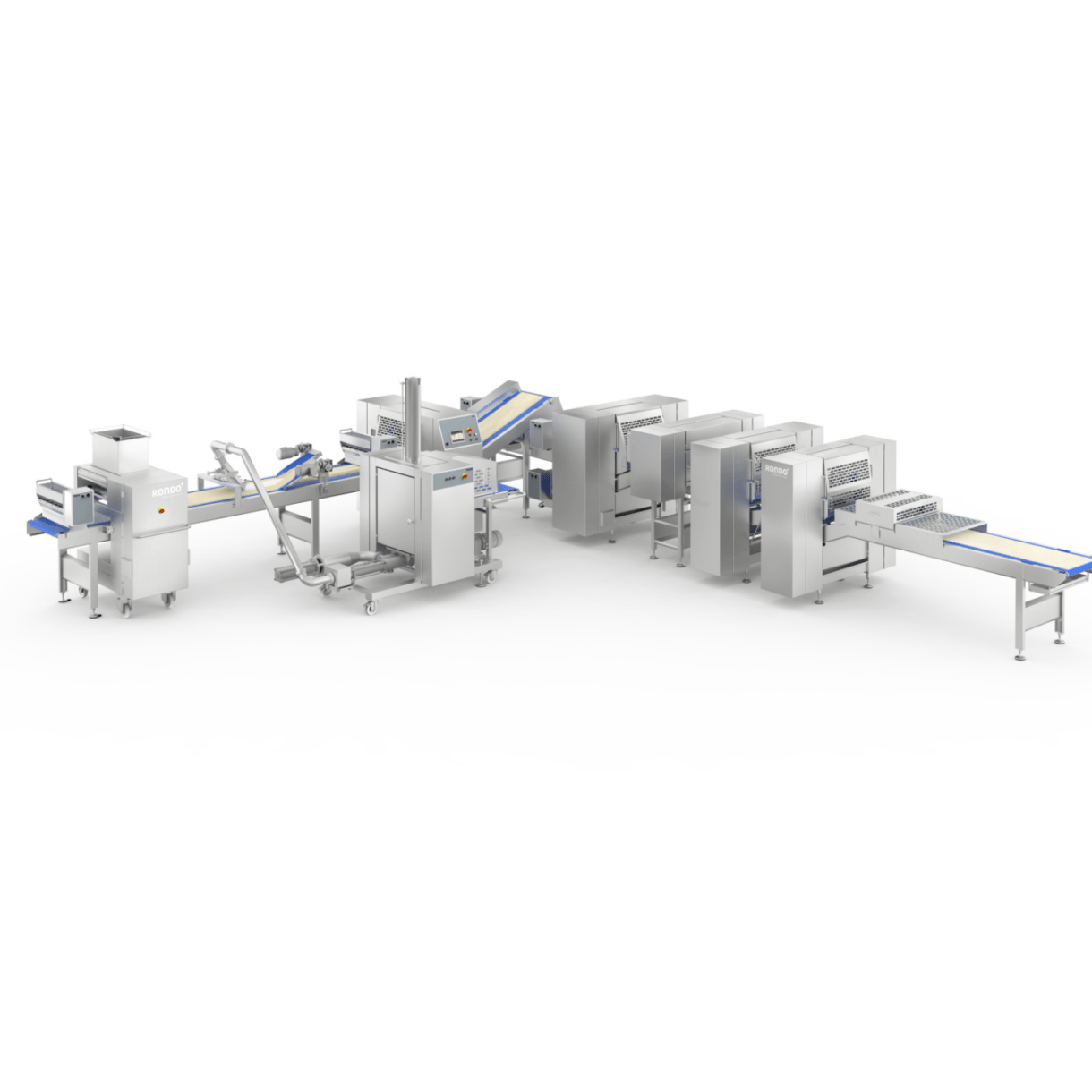

The MLC method is based on six modular systems that can be connected to each other at any time, without the need for changes in electrical systems and allows production mechanization to begin with a small system and grow together with the system step by step until a perfect production setup

.

With the help of the MLC, the dough/fat ratio is maintained throughout production at the same time as the precise folding of the dough, and the result is a high-quality, airy dough with the desired texture

Models to choose from: Block system – continuous feeding of a sheet of dough, manual fat placement and manual folding

- Block system with Fat – a pump is added to the above system to introduce fat into the dough

- Block system with sheeting Add satellite to the system for continuous sheeting

- L shape addition of an extra leg and a folding fan that enables automatic dough folding up to 32 leaves

- U shape extra leg for automatic folding of up to 144 leaves

- Orbital line addition of rolling and calibration for continuous feeding of dough to the production line

MLC increases production yields while saving maximum manpower that will be freed from the need to roll out the dough with rolling pins.

MLC enables the medium-sized manufacturer to start automatic and efficient production of dough at low costs and to grow with the array in the future.

With a conveyor width of 600 mm, the MLC can be adapted to any production setup for dough products. The computerized control panel In Hebrew Easy to program and save the production plans. The structure of the machine is made of stainless steel and is a guarantee for maximum cleanliness and hygiene.

For more information on the provider’s website.